With the water treatment network under increasing pressure from a growing population, significant upgrades are taking place. Temporary works, especially when these coincide with warmer weather, can lead to odour challenges from site works.

13th August 2025

The purpose of this article is to discuss the environmental impact of odour, and the solutions that can be put in place to mitigate it.

Unpleasant odours emitted from wastewater systems are primarily caused by the decomposition of organic matter and gases. Processes involving the storage, transfer and thickening of sludge will typically cause odour challenges.

Wastewater gases include:

• Hydrogen Sulphide (H₂S) – rotten egg smell

• Ammonia (NH₃) – sharp and pungent smell

• Volatile Organic Compounds (VOCs) – fatty acids that can produce musty or fishy odours

Be aware that in high concentrations these gases are both toxic and potentially flammable, and control methods should reflect this.

• Inlet works/ screens

• Primary clarifiers

• Sludge storage, thickening and dewatering

• Anaerobic digesters

• Open tanks or sumps

• Sewer overflows and pumping stations

An Odour Management Plan (OMP) is required where a site is within 400m of a sensitive receptor such as a neighbour and/or has a history of substantiated odour complaints. Furthermore, you may need to obtain an environmental permit issued under the Environmental Permitting Regulations 2016.

The EA publish a helpful document ‘H4 Odour Management’ giving guidance on how to comply with an environmental permit, this outlines:

1. Your Permit conditions and assessments

2. Control measures

3. Monitoring measures

It is your duty to ensure appropriate measures are put in place to minimise odours, as these can impact the public and are deemed an environmental nuisance. The Environment Agency states “Emissions from the activities shall be free from odour at levels likely to cause pollution outside the site, as perceived by an authorised officer of the Agency, unless the operator has used appropriate measures, including, but not limited to, those specified in an approved odour management plan, to prevent or where that is not practicable to minimise the odour”.

Failure to prevent environmental nuisance or comply with the odour management plan can lead to EA intervention, with the worst-case scenario leading to fines or work suspension.

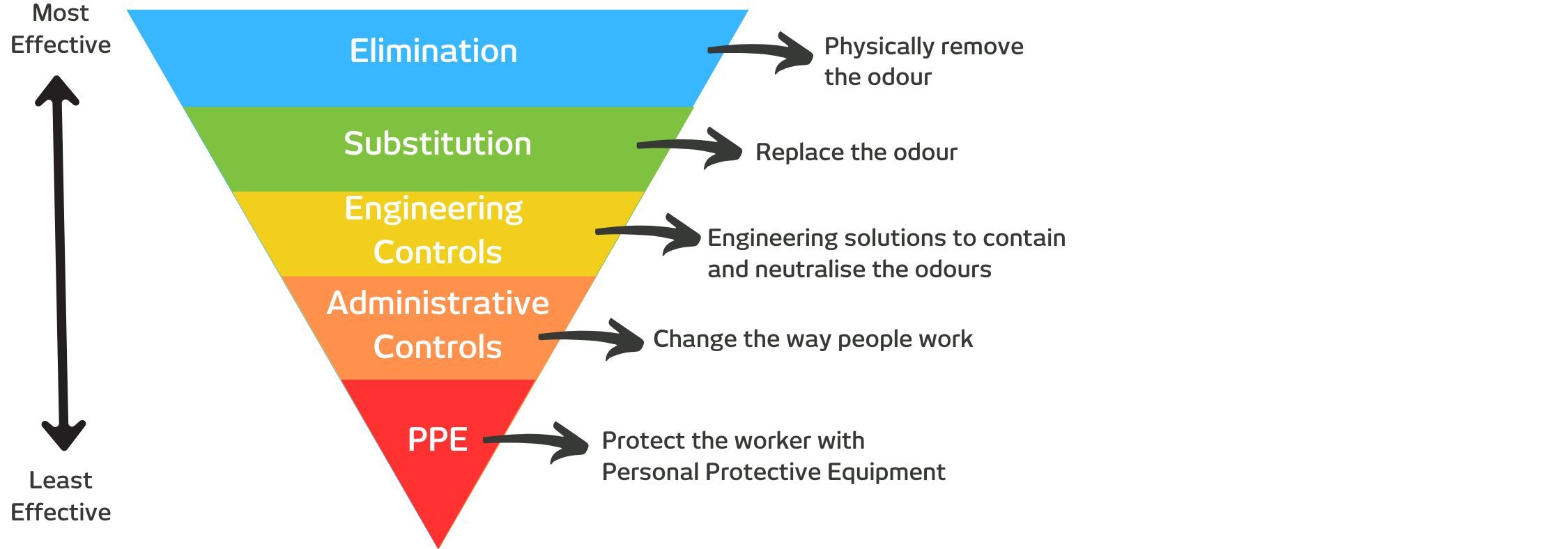

The hierarchy of controls helps us to tackle odours in a structured way, starting with the most effective measures at the top, progressing to the least effective at the bottom.

The next few paragraphs explain the common engineering methods used to control odours in the wastewater industry.

RVT have developed the 3C’s methodology for effective hazard control. This methodology can also be employed for odour control, for example, when dealing with sludge storage.

1. Capture the odour at source by extracting contaminated air through a carbon filter.

2. Contain the source by sealing the tanks or constructing temporary enclosures.

3. Control the migration of odour by creating a negative pressure, ensuring odour cannot leave the tank other than via the carbon filter.

Where it is not possible or practical to contain and extract at the source of the odour, airborne neutralisation can be employed across the site, using either water misting or evaporation techniques. These approaches are typically employed on a site-wide basis where odour is being generated from multiple sources and is impacted by wind and weather. So what options are available for odour neutralisation?

Rotary Atomisers – the chemical is dosed into feed water which is then emitted through a rotary atomiser. This creates a mist of very fine particles immediately in front of a fan which disperses it across an area.

Misting lines – the chemical is dosed into feed water which is then pumped at high pressure through a line with misting nozzles along it. The line is typically spread along a boundary or around a process.

Dry Vapour – a newer technology, odour neutraliser is heated and agitated, causing it to evaporate. It can then be emitted along a pipeline or in front of a fan for wider dispersal.

In some instance where H2S or other gases are emitted from water, chemical compounds can be dosed to prevent the formation and release of the gases. However, this requires a very project specific approach.

Note, whilst some odours can simply be masked with a stronger but less unpleasant smell, this approach is not encouraged.

• What is the specific source and cause of the odour?

• Can the source of the odour be eliminated?

• Can the source of the odour be contained?

• Can we adapt our work processes to reduce the odour being emitted?

• Consider the source-receptor pathway – where is the odour emitted and who is affected?

• Reflect on the environment and the control measures in place – will the direction of wind have an impact?

Our consultants are highly experienced at handling temporary odour control for applications including:

• Temporary sludge removal and thickening processes such as centrifuges

• Temporary sludge storage

• Clarifier and sludge tank emptying and cleaning tasks

We offer a wide range of mobile and static misting, fogging and carbon extraction systems, and can tailor a solution to your exact challenge.

At RVT, we don’t just provide solutions – we deliver assurance. We are passionate about protecting people and the environment, in the most efficient and effective way possible.

If you need support with controlling odours on site, then please contact an RVT consultant today or call 0808 178 3284.

Do you have a challenge on site? Enter your details below to get expert advice from a hazard control specialist.

We process your information in accordance with our Privacy Policy and Terms of Service.

A member of our expert team will contact you shortly to discuss your product requirements and solutions.