MVV Baldovie Energy from Waste (EfW) Combined Heat and Power (CHP) Facility is based in Dundee, Scotland. The MVV Baldovie EfW CHP facility had a scheduled three week plant shutdown to carry out various maintenance works within the furnace chambers, including activities such as welding, burning and grit blasting.

ChallengeWelders were scheduled to be working at the top of the furnace to carry out cutting and welding activities, welding fumes contain harmful particles from the material being welded and the electrode. Research conducted by the International Agency for Research on Cancer found that exposure to welding fumes, including mild steel welding, can cause lung cancer, so fume control was imperative.

The second area requiring support was the contractors carrying out grit blasting and small scale burning on the grate at the bottom of the furnace. The main concern was that fumes would rise up to where the welders were working.

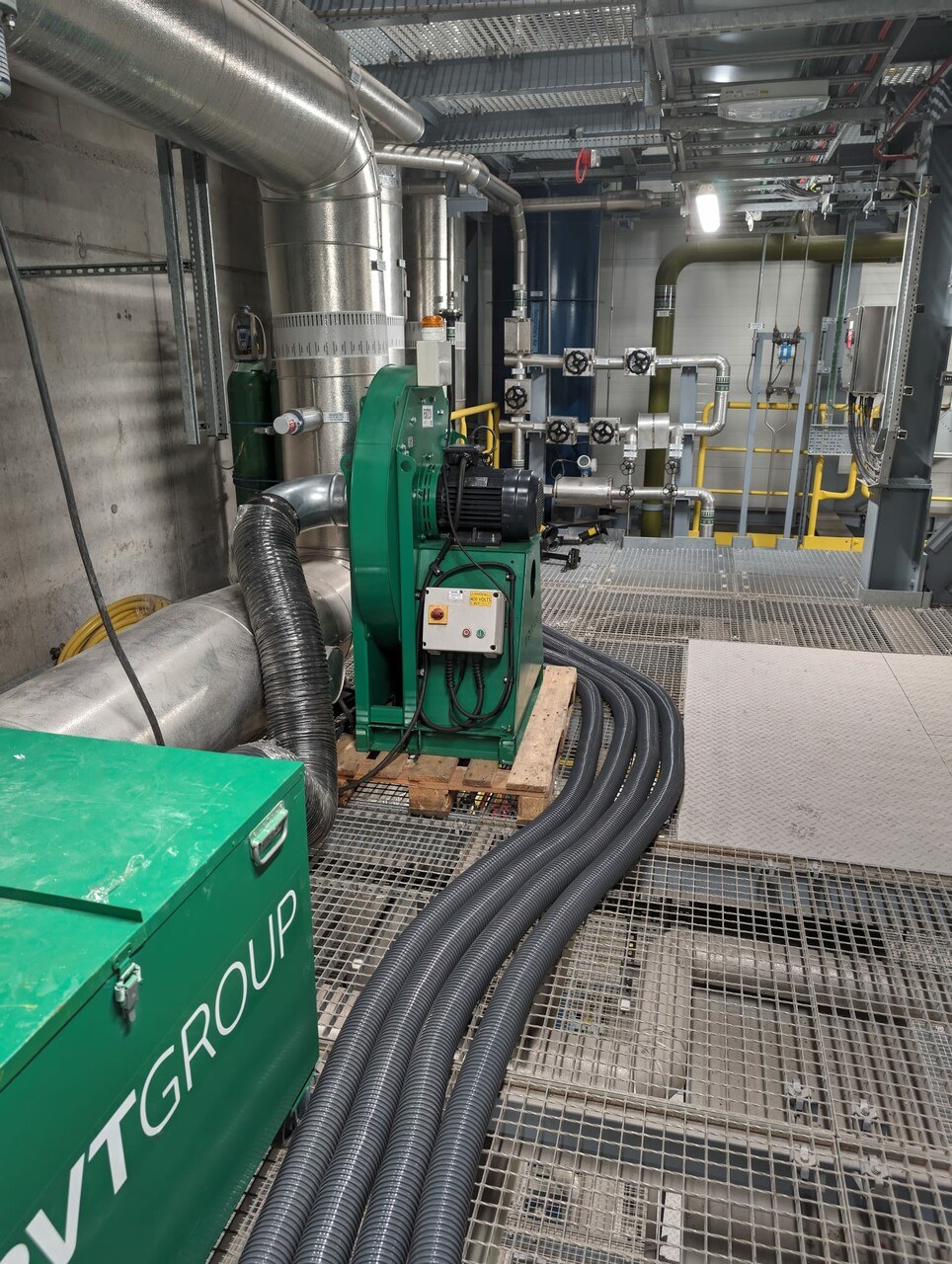

To protect the workers at the top of the furnace from welding fumes, RVT installed a VENTEX® 200S-HP Centrifugal fan in conjunction with RAVEX® Wandafilta Plus Kit, to create a mobile LEV system designed for fume extraction and filtration.

For the contractors carrying out grit blasting and small scale burning on the grate at the bottom of the furnace, we installed a VENTEX® 300M Centrifugal fan in conjunction with RAVEX® Wandafilta Plus Kit.

Following the implementation of RVT Group’s specialist hire equipment, workers and contractors were able to carry out the activities within a safe environment that protected their long-term health, the surrounding environment, and kept their productivity high with no visibility issues.

Client

MVV Baldovie Energy from Waste Combined Heat and Power Facility

Location

Dundee, Scotland